Purification is the process of removing undesirable chemicals, biological contaminants, suspended solids and gases from contaminated water. The goal of this process is to produce water fit for a specific purpose and reuse of treated water.

Innovative Filtrex™ Providing complete solutions for water & waste water treatment plants with consideration of advanced technologies.

Innovative Filtrex™ deliverable Products are :

Flat Sheet and Hollow Fiber polymeric membranes (Hydrophilic and Hydrophobic) with different MWCO and Thickness (For water and wastewater treatment, gas separation, pervaporation, desalination, forward osmosis, microbial fuel cell, and membrane distillation)

Polyvinylidene Fluoride (PVDF)

Polyether Sulfone (PES)

Polysulfone (PSf)

Polyacrylonitrile (PAN)

Cellulose Acetate (CA)

Polyether Imide (PEI)

Polyamideimide (PAI)

PolytetrafluoroEthylene (PTFE)

Nanocomposite Membranes

Mixed Matrix Membranes (MMMs)

Thin Film Composite Membrane (TFC)

Nanomaterials for Energy Storage Applications:

Metal-organic frameworks (MOFs) (For Energy storage, Gas Storage, separation, catalysis, sensing and water treatment applications): ( All metal ions and organic linkers available)

Purification takes the refinement of substances to the highest level. It involves the meticulous removal of impurities or contaminants, ultimately resulting in an elevated degree of quality & purity. Purification is a multi-step process that often includes filtration & separation. However, it goes a step further by incorporating tailored chemical treatments or processes specifically designed for the substance being purified. In industries like healthcare, electronics manufacturing, & water purification, where product integrity & adherence to safety standards are non-negotiable, purification is of paramount importance.

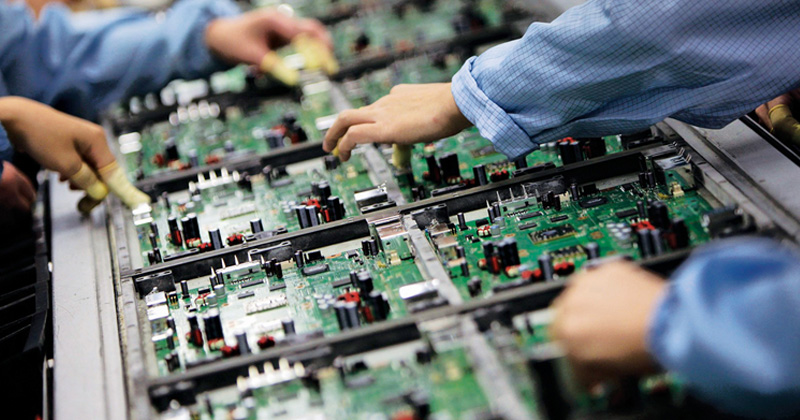

In electronics manufacturing, where precision & performance are sacrosanct, purification is a critical step in guaranteeing that microchips & components exhibit exceptional precision & functionality.

In summation, these three intrinsic processes—filtration, separation, & purification—constitute the linchpin of a myriad of industries. They stand as the bedrock of endeavours aimed at elevating product quality, facilitating unwavering compliance with stringent regulatory standards, & guaranteeing the steadfast reliability of pivotal industrial processes. As a testament to our expertise, we specialize in crafting & implementing meticulously tailored solutions that seamlessly integrate these processes to cater to your unique & specific requirements.

In the healthcare sector, purification emerges as the vanguard ensuring that medications, medical devices, and healthcare products are entirely free from any trace of contaminants. The integrity and safety of these products are paramount, and purification techniques are instrumental in upholding these standards.

Water purification, too, assumes a place of utmost significance, as it serves as the cornerstone for providing clean and safe drinking water to communities across the globe. Here, purification techniques are the guardians ensuring that waterborne contaminants, from microorganisms to chemicals, are meticulously eliminated, safeguarding public health.